|

Tensile Bond Strength of Panavia Ex to a Ni-Cr Alloy Using Different Surface Treatments

Claudia Mendonça PINTO COELHO[1]

José Henrique RUBO[2]

Luiz Fernando PEGORARO[2]

[1]Hospital de Reabilitação,

[2]Departamento de Prótese, Faculdade de Odontologia, USP,

Bauru, SP, Brasil

Braz Dent J (1995) 6(2): 111-114 ISSN 0103-6440

| Introduction | Material/Methods

| Results and Discussion | Clinical

Implications | Conclusions | References

|

Panavia Ex resin has been claimed to require only air abrasion of the

alloy with 50 µm aluminum oxide particles to reach acceptable bond

strength values. This study discusses the consequences of changes in the

type of air abrasion and surface oxidation of the alloy. Thirty pairs of

discs of a Ni-Cr alloy were treated by three methods: 1) air abrasion with

50 µm aluminum oxide (control); 2) air abrasion with glass beads;

3) air abrasion with a mixture of aluminum oxide and glass beads (ratio

1:1). The Tukey test showed statistical differences only for air abrasion

with glass beads.

Key words: resin-bonded prostheses, surface treatments.

Introduction

The construction of resin-bonded prostheses has been simplified with the

development of resins that bond chemically to both enamel and air-abraded

base metal alloys (Omura et al., 1984). One of those resins, Panavia Ex,

has been reported to require only air abrasion of the alloy with 50 µm

aluminum oxide particles and ultrasonic cleaning to reach acceptable bond

strength values (Pegoraro and Barrack, 1987).

However, much research has been carried out (Tanaka et al., 1986; Wiltshire,

1986; Caeg et al., 1990; Kohli et al., 1990; Lin et al., 1990; Turner and

Sinclair, 1990; Kolodney et al., 1992) in order to determine which surface

treatment would be the most suitable. The purpose of this study was to

evaluate the effect of different types of air abrasion and surface oxidation

treatment on the bond strength of Panavia Ex to a Ni-Cr alloy.

Material and Methods

Thirty pairs of discs of a Ni-Cr alloy (Durabond MS, Dental Gaúcho

Marquart e Cia Ltda, São Paulo) were obtained from wax patterns

made in a matrix 2.0 mm in thickness and 10.0 and 12.0 mm in diameter.

A standardized loop was placed over the discs as an attachment to the testing

machine.

After casting, the discs were cleaned and their surfaces ground with

a 600-grit sandpaper to obtain two parallel flat surfaces. They were then

subjected to four thermal cycles to simulate a porcelain firing surface.

In order to align the two discs during cementation a metallic cylinder

was used with a central slit and two concentric bases with two different

diameters: the bottom with 10.0 mm in diameter by 3.0 mm in height and

the upper 12.0 mm in diameter by 1.0 mm in height.

To standardize the space for the luting agent, we used the methodology

described by Rubo (1989). The two metal specimens were fixed surface to

surface with 60-µm thick adhesive tape (Scotch double face adhesive

tape, 3M Ltda). To keep these discs in position inside the cylinder, acrylic

resin (Duralay, Relliance Dental Mfg Co., Worth, IL, USA) was added on

the external surface of discs. The larger disc was held in position by

the shoulder in the cylinder. After curing the resin the tape was removed

and the space for the luting agent standardized.

Before cementation the surfaces were treated by three methods: 1) sandblasted

with 50 µm aluminum oxide (Odonto Larcon, São Paulo) with

75 lbs air pressure; 2) sandblasted with glass beads (Odonto Larcon, São

Paulo); 3) sandblasted with a mixture of aluminum oxide and glass beads

(ratio 1:1). All of the specimens were ultrasonically cleaned in distilled

water for 2 min before cementation.

Dental Panavia Ex (Kuraray Co., Japan) was mixed according to the manufacturer's

instructions, applied to the internal surfaces of the two discs and kept

under a 5-kg load. The discs were stored in distilled water at 37°C

for 24 hours and the tensile bond strength was measured in a universal

testing machine (Dinamômetros Kratos Ltda, São Paulo) at a

crosshead speed of 0.5 mm/min.

Results and Discussion

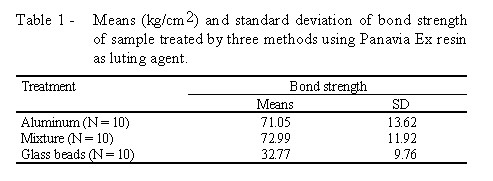

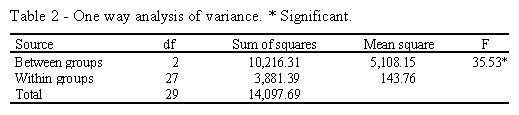

Tensile bond strength of the samples treated by three methods (Table 1)

were compared by one-way analysis of variance to verify the difference

among surface treatments (Table 2). Analysis identified significant differences

between treatments and interactions between them. The Tukey test for multiple

comparisons revealed significant differences between the following treatments:

1) aluminum oxide x glass beads; 2) mixture of aluminum oxide and glass

beads x glass beads.

Improper surface treatment of the alloy has been responsible for failures

in the interface metal/luting agent. The correct use of abrasive powders

in the dental laboratory is essential to improve the bond strength of metal/resin/enamel.

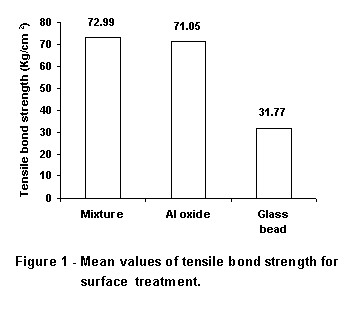

From the data obtained it could be observed that the surface treatment

with glass beads decreased the bond strength more than 50% when compared

to other conditions (Figure 1). Since the glass beads are less abrasive

than the aluminum oxide particles they could smooth the surface whereas

the aluminum oxide would roughen it. It could be concluded that the aluminum

oxide not only increases the reaction on the surface with resin but also

creates micromechanical retention increasing bond strength.

The devices used for air abrasion are often composed of three compartments:

one with aluminum oxide, one with glass beads and the third which collects

the other two after their use. Negligence in the use of this device may

result in improper air abrasion. Regardless of the result obtained with

the mixture of aluminum oxide and glass beads, its use is not advisable.

The ratio between the two powders can become critical compromising the

bond strength. The powders used in this study were mixed before use.

Therefore, it can be concluded that the bond strength between resin

and metal is due in part to the mechanical retention obtained by sandblasting

and in part to chemical adhesion of the resin to the metal.

Differences found between this study and others in the literature, including

Tanaka et al. (1986) who found values 3 times superior, can be explained

by differences in the methodology used, crosshead speed of the testing

machine, type of alloy and resin, shape and size of specimens. This makes

direct comparisons impossible. However, there is agreement with the study

of Rubo (1989) (mean value of 78.30 kg/cm2) who used the same methodology.

Clinical Implications

Since the development of resin-bonded prostheses, researchers are seeking

an effective and easy-to-use system of bonding resin to metal. Air abrasion

with aluminum oxide has satisfactorily fulfilled these conditions. At this

time any attempt to improve this system has shown to be unnecessary. On

the other hand, attention to correct air abrasion is imperative for success.

Conclusions

1) Bond strength of the samples was greatest with a mixture of aluminum

oxide and glass beads 1:1, followed by aluminum oxide, and glass beads.

2) The Tukey test showed statistical differences only for air abrasion

with glass beads.

References

Caeg C, Leinfelder KF, Lacefield WR, Bell W: Effectiveness of a method

used in bonding resins to metal. J Prosthet Dent 64: 37-44, 1990

Kohli S, Levine WA, Grisius RJ, Fenster RK: The effect of three different

surface treatments on tensile strength of the resin bond to nickel-chromium-beryllium

alloy. J Prosthet Dent 63: 4-8, 1990

Kolodney Jr H, Pucket AD, Breazeale MS, Patterson KL, Lenz DL: Shear

bond strengths of prosthodontic adhesive systems to a nickel-chromium-beryllium

alloy. Quintessence Int 23: 65-69, 1992

Lin T, Chang H, Chung K: Interfacial strengths of various alloy surface

treatments for resin-bonded fixed partial dentures. J Prosthet Dent 64:

158-162, 1990

Omura J, Yamauchi J, Harada I, Wada T: Adhesive and mechanical properties

of a new dental adhesive. J Dent Res 63: 233 (abstract), 1984

Pegoraro LF, Barrack G: A comparison of bond strengths of adhesive cast

restorations using different designs, bonding agents, and luting resins.

J Prosthet Dent 57: 133-138, 1987

Rubo JH: Tensile bond strength of Panavia Ex to various dental alloys.

Master's thesis, School of Dentistry of Bauru, University of São

Paulo, Brazil, 1989

Tanaka J, Fujiyama E, Shimizue A, Takaki A, Atsuta M: Surface treatment

of non-precious alloys for adhesion-fixed partial dentures. J Prosthet

Dent 55: 456-462, 1986

Turner CH, Sinclair L: Sprayed opaque porcelain as a surface for resin-bonded

restorations. Int J Prosthodont 3: 384-390, 1990

Wiltshire WA: Tensile bond strengths of various alloy surface treatments

for resin-bonded bridges. Quintessence Dent Tech 10: 227-232, 1986

Correspondence:Claudia Mendonça Pinto Coelho, Rua Quintino

Bocaiuva, 1006, 14015-160, Ribeirão Preto, SP, Brasil.

|